Established in 1980, Kıvanç Group (headquartered in İstanbul) operates in four divisions: Safety, Technical Textile, Engineering and Mining. In Safety division, personal protective clothing against heat and flame, static discharges, arc flashes, molten metals, welding spatters and chainsaw are produced. Our Sinop factory manufactures flame-resistant and antistatic protective garments for firefighters, search and rescue teams, and workers in energy, petrochemical, and heavy industries. Military flight suits, tank crew uniforms, and camouflage clothing are also manufactured for defense and security forces.

.jpeg)

Freedom of Movement with SuperStretch Knee and Elbow System the most advanced layer system in the market segmented reflective tapes (comfortable, easy movement) glow in the dark photolumiscence tapes (silhoutte visible in total darkness, visible in 200 m distance, 5 minutes charge with solar energy, 10 minutes charge with lamp energy, 8 hours of illumination with full charge) ergonomic pockets (bellow pocket, hidden side pocket) DRD (easy removal of firefighter in case of emergency with the rescue belt located on the back yoke) ready to use tunnel system for chest belt, and openings for integration with sit harness and full body harness

In search & rescue operations, maximum visibility is just as important as lightness and comfort! Superior mobility due to lightweight design: only 220g/m2 Made of our innovative multi-norm fabric Opti-syn Available in 3 stunning color options: red/hi-vis yellow, Gold/hi-vis yellow, Dark Blue/hi-vis yellow Maximum visibility under all conditions even after 50 washing cycles Maximum comfort due to the effective pattern and design and with user-friendly practical details such as extra pockets. Extra abrasion and cut resistance protection in the zones where it is most required. Fully complies with international standards! Meets with EN ISO 15384:2020, EN 15614:2007, EN 16689:2017, EN ISO 13688:2013/A1:2021, EN ISO 11612:2015, EN 1149-5:2018.

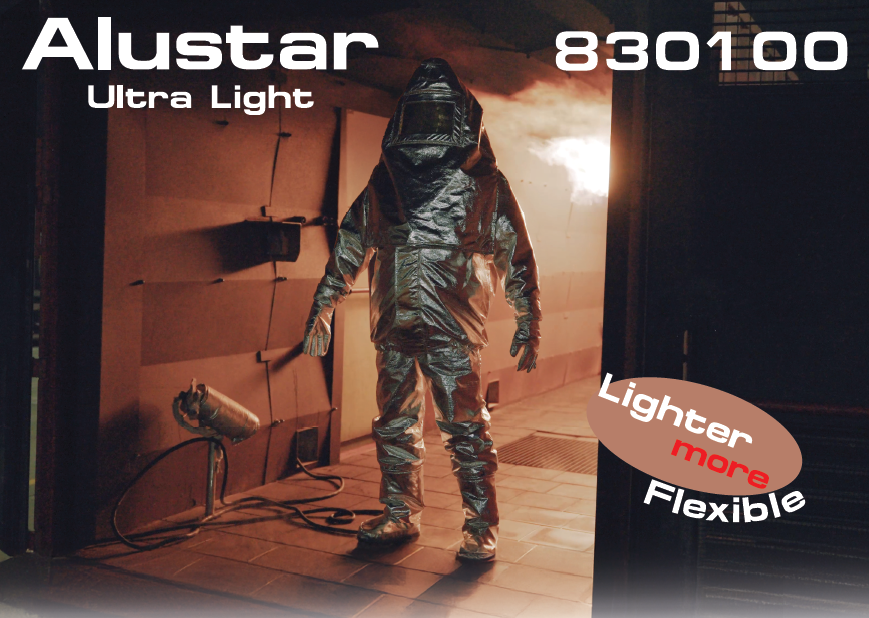

This aluminized suit is designed to protect the wearer against high radiant, convective and contact heat. The products in this set consist of outer shell, moisture barrier and heat barrier and are produced in line with EN 1486 standard. The set contains the following items: jacket with back space for covering SCBA cylinders trousers, shroud with gold coated visor and EN 397 certified helmet, gloves, gaiters with EN 15090 certified rubber boots, carrying bag This suit may be used in proximity firefighting, front or inside ovens during maintenance, glass or iron & steel industries in front of molten glass or metal, areas where there is high radiant heat.

.jpeg)

MARKUS combines maximum protection, visibility, and comfort in one lightweight design. Weighing only 220 g/m², MARKUS is at least 10% lighter than industry standards—ensuring enhanced mobility and reduced fatigue in high-heat environments. Its ergonomic fit supports optimal ventilation. Made from our innovative multi-norm fabric Opti-Syn. Visibility and functionality are critical in wildland operations. MARKUS features premium 3M reflective tapes and has multiple practical pockets. Available in four colors—Yellow, Gold, Red, and Dark Blue—MARKUS ensures responders stay seen and ready, wherever the fire takes them. Certified according to: EN ISO 15384:2020, EN ISO 13688:2013/A1:2021, EN ISO 11612:2015, EN 1149-5:2018.

Opti-Syn Elastane: High Mobility, Superior Comfort, and Protection – All in One! We integrated stretch—common in everyday wear but rare in protective gear—into Opti-Syn, redefining fabric standards. Its unique texture, yarn, and fibre blend enhance comfort, wick moisture, and dry quickly. Natural, skin-friendly fibres offer a softer wearing experience versus synthetic aramids. Through extensive R&D, we developed Opti-Syn Stretch: a fabric that boosts mobility and comfort in demanding work. It targets stress zones in areas like legs, arms, back, and shoulders—ensuring freedom of movement where it's needed most.

Forestar chainsaw protective clothing is designed for logging operators. Thanks to its special protective layer, it stops the chainsaw and prevents the person from being harmed. Forestar is the first EN 381 certified product manufactured in Turkey.

Two-way front zipper Velcro tapes on right and left chest to put chevrons Inclined chest pockets closed by zipper Left sleeve bellow pocket with flap on pocket with zipper Adjustable cuffs with Velcro tape Elastic drawcord on waist, fixed by Velcro tape Back bellows for comfortable movement Knife pocket on the left trouser leg Right trouser leg pocket closed by zipper Asymmetrical pocket on the left trouser leg Zipper: Molded zippers with Aramid tape Fabric composition: 99% Aramid, 1% Antistatic Fabric weight: 160 gr/m2 Weaving type: 1/1 Plain Protection Performance: EN ISO 11612 A1 A2 B1 C1 F1 , EN 1149-3 & EN 1149-5

Grey reflective tapes on the shoulders and lower back of the legs Velcro tapes on right and left chests to put chevrons Inclined chest pockets closed by means of zipper Elastic drawcord on waist, fixed by Velcro tape Drag and rescue system on the back, enclosed by zipper Back bellows for comfortable movement "U"-shaped opening on the back of the coverall Outershell material reinforced crotch Pockets on the lower legs closed by zipper Adjustable lower leg width with zipper Elastic drawcord at leg hems Molded zippers with Aramid tape Heat and flame resistant, high-strength Aramid woven rescue belt Fabric composition: 93% Meta-Aramid, 5% Para-Aramid, 2% Antistatic Protection Performance: EN ISO 11612 A1 A2 B1 C1 F1 , EN 1149-3 & EN 1149-5

Front zipper Epaulets on the shoulders for rank Velcro tapes on both sides of the chest for chevrons Left sleeve with a bellows pocket featuring a flap and zipper Back bellows for enhanced comfort and freedom of movement Heat- and flame-resistant knitted cuffs and jacket hem Heat- and flame-resistant inner lining Interior pocket on the left chest Molded zippers reinforced with aramid tape Fabric composition: 93% Meta-Aramid, 5% Para-Aramid, 2% Antistatic Fabric weight:160 gr/m2 Weaving type: 1/1 Plain Colour:Dope dyed Heat Barrier: Aramid nonwoven quilted to Aramid/Viscose FR inner lining Knitted Rib Fabric: 550 gr/m2 (96% Aramid, 2% Elastane, 2% Antistatic) Protection Performance: EN ISO 11612 A1 A2 B1 C1 F1 , EN 1149-3 & EN 1149-5

JACKET Front flap closed by buttons Foldable collar closed by button Epaulets on the shoulders for rank Velcro tapes on chest and sleeves Bellow chest pockets closed by buttons Bellow pockets on sleeves Elbow reinforcements Pen pockets on both arms Adjustable waist and cuffs with buttons Back bellows for comfortable movement TROUSERS Side pockets Side bellow cargo pockets with the flaps Bellow small trotter pockets with the flaps Pleated pockets with the flaps on the back Trotters with the elastic drawcord Reinforced crotch Outershell material reinforcement on the knees 50% Cotton, 50% Polyamid 6.6 205-225 gr/m2 1/1 Plain Ripstop Colour: IR+Camouflage printed The water repellency and properties are resistant at least to 20 wash cycles.

JACKET The front flap is closed by means of zipper Half lined jacket Epaulets for rank on the shoulders Inclined pleated pockets on right and left chests with flaps Pockets on the right and left sleeves Adjustable cuffs by means of Velcro tape Back bellows for comfortable movement TROUSERS Trousers closed by means of zipper and metal hook Two belt pockets and two back pockets closed by means of Velcro tape Side cargo pocket with flaps Outershell material reinforcement on the knees with zipper system to insert padding Fabric composition: 50% Cotton, 50% Polyamide 6.6 Fabric weight: 205-215 gr/m2 Weaving type 1/1 Plain Ripstop Colour: Base dyed and camouflage printed (High colour fastness)

JACKET Hidden buttons on the front flap Inclined chest pockets closed by means of a zipper Elbow reinforcements Adjustable cuffs by means of buttons Back bellows for comfortable movements and embroidered holes for air flow on the armpits TROUSERS Trousers flap buttons match with the outershell fabric colour Hidden back pockets with flaps Side bellow cargo pockets with flaps Bellow pocket on the right trotter Trotters with elastic drawcord Reinforced crotch Outershell material reinforcement on the knees 65% Cotton, 35% Polyester 220-230 gr/m2 2/2 Twill Ripstop Colour: Base dyed and camouflage printed (High colour fastness). The water repellency and antibacterial properties are resistant at least to 20 wash cycles.

Thanks to the special fiber composition, the underwear is heat and flame resistant. The underwear is specially designed for military response teams, firefighters, and industrial workers exposed to high temperatures. Thanks to its antistatic properties, underwear ensures the discharge of static charge, prevents explosions caused by fuel&gas vapors. Since underwear is made from inherently FR fibers, its properties will not change over time, washing, or wear. Features include a round collar, long sleeves, long johns, skin-friendly breathable technical knit, and 100% Aramid sewing thread. 93% Meta-Aramid, 5% Para-Aramid, 2% Antistatic 190 gr/m2 Knitted Interlock Colour: Ecru, Khaki, Dark Blue EN ISO 11612 A1 A2 B1 C1 F1 , EN 1149-3 & EN 1149-5

Balaclava protects the head, face, and neck areas which are not covered by clothing, helmet, etc. It is constructed according to the EN 13911 standard. Ergonomic design fits the shape of the head and neck, with a specially designed face opening and stitching that prevents bulkiness in the seam area for comfortable, skin-friendly wear. Made with 100% aramid sewing thread. Fabric composition: 93% Meta-Aramid, 5% Para-Aramid, 2% Antistatic Fabric Weight: 220 gr/m2 Fabric Type: Knitted Interlock Colour: Dope Dyed khaki, dark blue, ecru Protection Performance: EN ISO 11612 A1 A2 B1 C1 F1 , EN 1149-3 & EN 1149-5

Made of PBI Matrix fabric Para-aramid knitted inner lining Waterproof and breathable membrane The palm, knuckles, finger joints and fingertips are reinforced with silicon/carbon coated para-aramid fabric. Flame resistant photoluminescent tape with glow in the dark effect Para-aramid knitted cuff Material: PBI Matrix Color: Gold/Black Certificate: EN 659:2003 + A1:2008 + AC:2009 EN21420:2020 Size: 6-13 according to EN 659 and EN 21420

Fire helmet Vulcan NEO is an innovative design. It is made entirely of composites by direct injection method. It has excellent protection, use convenience and design. It complies with Regulation (EU) 2016/425 and the following harmonised standards: EN 443:2008 Helmets for firefighting in buildings and other structures. EN 16471:2014 Firefighters helmets. Helmets for wildland fire fighting. EN 16473:2014 Firefighters helmets. Helmets for technical rescue. EN 50365:2002 Electrically insulating helmets for use on low voltage installations, confirmed by a certificate issued by Notified Body No. 0497 CSI S.p.A. Certificate of admittance issued by Notified Body No. 1438 CNBOP-PIB.

Kıvanç Group has been representing Haix fireman leather boots and rescue boots in Turkey for over 10 years. The new generation. Light & highly innovative. Model: 507501 Certificates: CE 0197 EN 15090:2012 HI3 CI M SRC – Typ F2A Material: 2.0 – 2.2 mm thick waterproof leather Color: Black Inner Lining: CROSSTECH® Leg height: 23 cm Sole: 017, antistatic Available sizes: EU 36 – 47 Extra large sizes: EU 48 – 50

One of our latest fire suits Optimus, stands out not only by its excellent design but also with being an economical solution. Available in gold, dark blue and red color, outstanding features in Optimus design: glow in the dark photolumiscence tapes (silhoutte visible in total darkness, visible in 200 m distance, 5 minutes charge with solar energy, 10 minutes charge with lamp energy, 8 hours of illumination with full charge) control of the inner layers is ensured with a zippered inspection opening suspender system with shoulder padding unique design with red trims and segmented silver reflective stripes

In Engineering Division, thermal insulation applications to reduce the heat loss are done by using high temperature resistant glass fiber based materials. We manufacture removable insulation pads for turbines, plastic injection molding machines, textile dying machines, exhaust parts of vehicles, valves etc. Correct materials are used by calculating the heat loss, minimum thickness of insulation, surface temperature etc. Thermal imaging cameras are used to find the heat loss areas. Machine equipment insulations, textile compensators, fire blankets, smoke screens and welding blankets are produced by using glass fiber based materials.